Aware of the risks associated with climate change, the Vietnamese agricultural sector is entering a new "revol...

Aware of the risks associated with climate change, the Vietnamese agricultural sector is entering a new "revolution" as more and more companies transform their shelf production models into circular ones. This new journey not only helps to "cure" environmental damage after a long period of production and cultivation in search of productivity, but also helps to open up bright prospects for agricultural products and processed products of Vietnamese agricultural products to reach the international market.

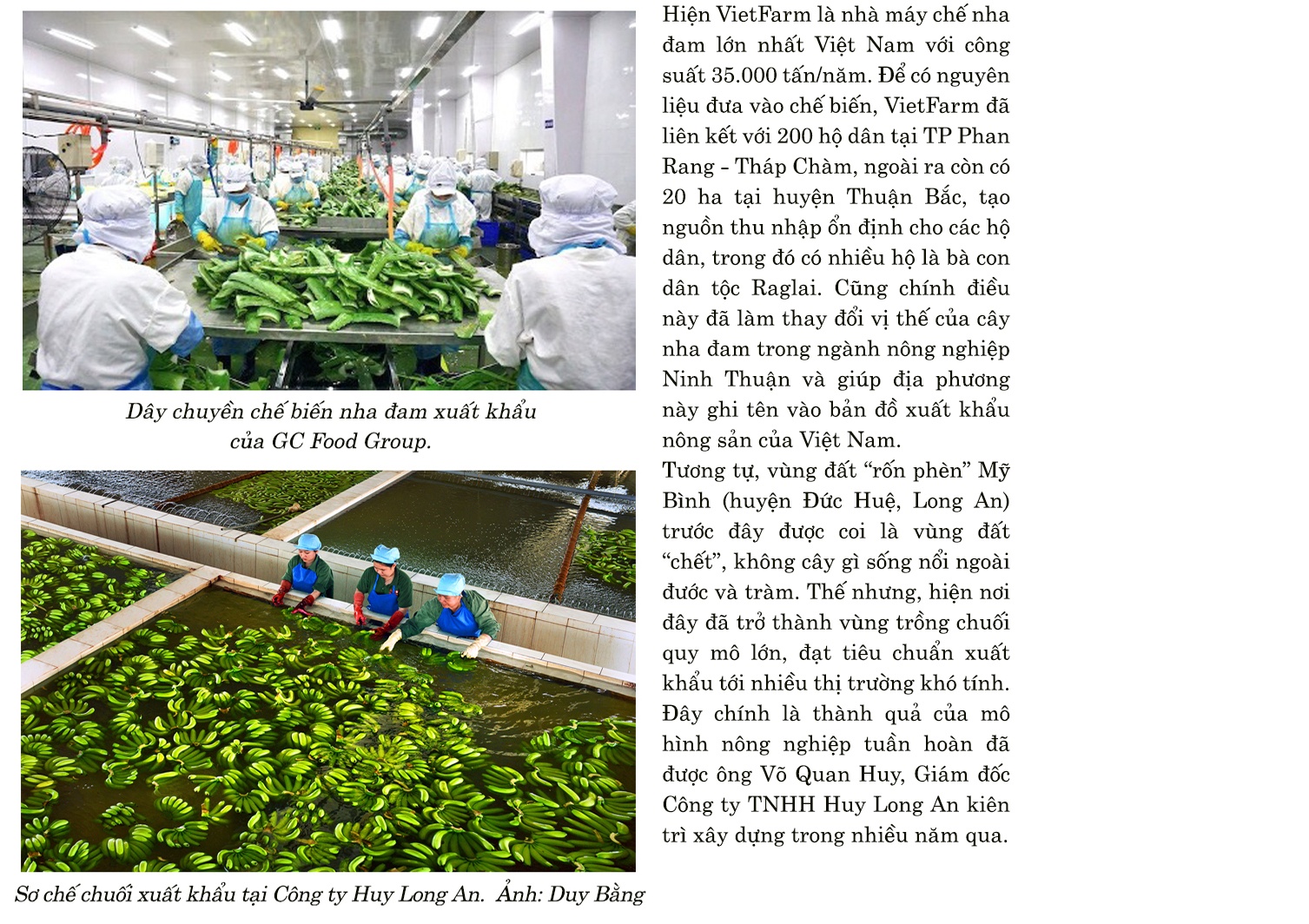

Upon entering Viet Dong Food Joint Stock Company (VietFarm) aloe vera export plant - member of GC Food Group in Phan Rang City - Thap Cham, Ninh Thuan Province, our first impression is a large mural just in front of the factory with the slogan: «Create a happy world by providing a happy food chain». Behind this fresco, things are even more impressive. It is the fact that GC Food has built a closed process, creating a new life cycle for the by-products in the production process.

Presenting his company’s circular farming model, Mr. Nguyen Van Thu, President of GC Food Group, said that while other vine or apple growing companies can cost tens of millions of VND of fertilizer per hectare per year, At GC Food, the amount of inorganic fertilizer to use for these agricultural areas is negligible as most of them are self-produced organic fertilizer source from leafy grass, aloe vera as well as cow manure, sheep compost. This has reduced production costs and producer prices are still comparable to those of conventional products.

Combining agriculture and livestock in a closed cycle from factory to farm, Thu said the company’s agricultural production process produces absolutely no waste. “Recently, the price of inorganic fertilizers has gone up, but we have not been significantly impacted. With a proportion of about 20 to 30% of production costs, the use of organic microbial fertilizers produced by companies not only reduces production costs, reduce product costs, benefit consumers, but also helps to minimize environmental impacts, create clean products and develop sustainably,” said Mr Thu.

Agriculture has long been a thorny sector of the Vietnamese economy with many competitive advantages such as arable land, forest cover, territorial waters, tropical climate, abundant labor and profitability. However, due to geographical conditions, Vietnam is particularly vulnerable to climate change and the agricultural sector in particular is severely affected. In response, the government is focusing on addressing one of the most challenging challenges – climate change – to help the agricultural sector grow sustainably and continue to shine, thus contributing to Vietnam’s emissions balance-sheet objective.

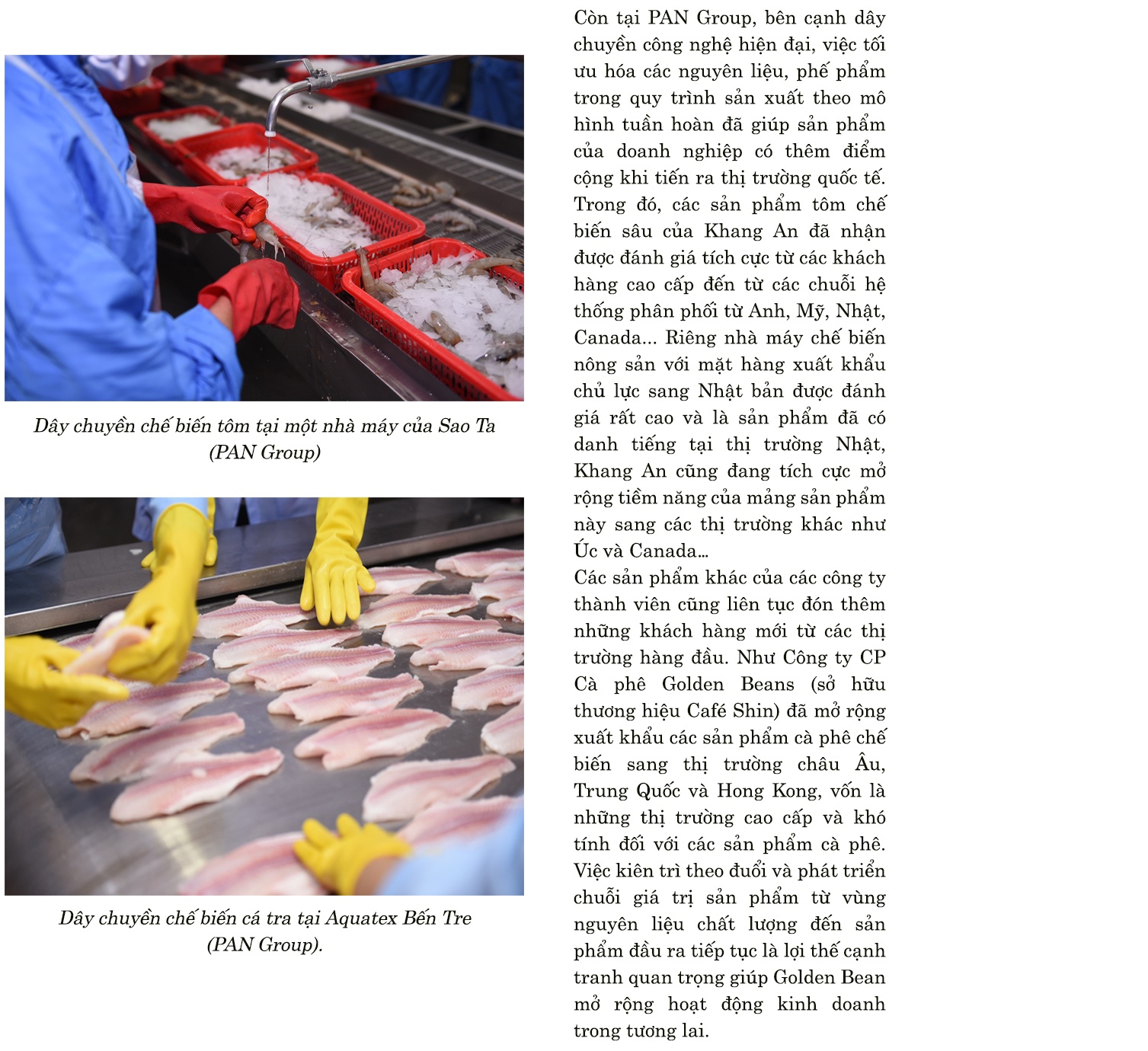

Supporting the government in this important goal, agricultural companies are becoming more proactive and serious in developing and implementing their sustainable development strategies. from circular economy models to sustainable supply chains. Companies are paying more attention to green agriculture, not only to help Vietnam reduce carbon emissions in agricultural production, but also to meet the growing demand for sustainable products in export markets. As a result, in addition to GC Food, Vietnam’s circular agriculture has many companies, from big names such as PAN Group, Vinamilk, TH True Milk, Vinamit, TTC AgriS, Nestlé Vietnam to small businesses such as Huy Long An, HG Farm and even cooperatives.

Huy Long An Co., Ltd. also implements a circular agriculture model on an area of 240 hectares in the municipality of My Binh, Duc Hue district, Long An province. Accordingly, in the production process of exporting old bananas, bananas do not meet the size standards, The color will be removed to make feed for cows. Cow manure is dried, sprayed with probiotics for treatment, and then mixed with organic fertilizer to provide nutrients to banana orchards and other fruits such as grapefruit, mangosteen, pastures for cows to eat. In addition, waste from banana stems and weeds after cutting is also ground and composted to create biomass to increase moisture and loosen the soil.

Vo Quan Huy said that the organization of agricultural production according to the circular model was not the goal set from the beginning, but stemmed from the need to improve soil contamination by alum to save crops. After several unsuccessful attempts to use chemicals to wash alum, he found that using compost was the best solution. So far, the farm’s circular farming model has proven to be globally effective, both in terms of the quality of the products created in the chain and in terms of increasing economic value and compliance with environmental requirements for sustainable development. Currently, Mr. Vo Quan Huy is also reproducing this model in other farms of the company in other localities such as Tay Ninh, Dong Nai, Binh Duong, Lam Dong with many crops such as bananas, grapefruits, avocados...

Vo Quan Huy said that the organization of agricultural production according to the circular model was not the goal set from the beginning, but stemmed from the need to improve soil contamination by alum to save crops. After several unsuccessful attempts to use chemicals to wash alum, he found that using compost was the best solution. So far, the farm’s circular farming model has proven to be globally effective, both in terms of the quality of the products created in the chain and in terms of increasing economic value and compliance with environmental requirements for sustainable development. Currently, Mr. Vo Quan Huy is also reproducing this model in other farms of the company in other localities such as Tay Ninh, Dong Nai, Binh Duong, Lam Dong with many crops such as bananas, grapefruits, avocados...

HG Farm Co., Ltd. circular farming model on alum contaminated land in Hau Giang is also a typical example of raw material optimization, bringing environmental benefits, adaptation to climate change and economic benefits. With 4 chains of mushrooms - cows - ducks - rice and green energy from solar energy, no organic matter is neglected in HG Farm. All are priority to be converted into animal feed, then into fertilizer to optimize biomass energy.

In all agricultural production chains, the consumer market for products is always an extremely important piece of the puzzle. It also demonstrates the efficiency and sustainability of the chain in the future.

Noting that in companies implementing circular production, the common point is easy to see is that the path to the market, especially the fastidious export markets with high standards, is much more favorable, and high growth potential. Ecological and circular production processes are becoming a priority to help goods develop export markets more easily. Because to have quality products, meeting the quality standards of the importing country, the source of raw materials is a prerequisite. The circular production model helps companies to eliminate almost all chemicals, chemical fertilizers and phytosanitary drugs during the growing process, creating high quality raw materials as inputs for the production of companies. Input quality is the premise of a practical and open output.

Similarly, Fohla brand bananas from Huy Long An have also been exported to many markets such as Malaysia, Korea, China and especially the Japanese market with particularly strict standards. Mr. Vo Quan Huy explained that the Fohla brand means “Fruit of Huy Long An”, which means the fruit of Huy Long An. Currently, the export volume of Fohla bananas reaches thousands of tons per year. Despite the epidemic period of Covid-1919, the company’s export activities remained stable, even growing well.

Similarly, the joint stock company Nha Trang 584 Seafood received the first export orders to the US and Korea, which helped diversify the market. Lafooco has also recently received orders from new customers such as a large supermarket chain in Japan and some customers in China. Previously, in 2022, the commercial nut snack product Lafooco entered the top 10 best-selling cashew snack products after only 2 weeks on Amazon...

Similarly, the joint stock company Nha Trang 584 Seafood received the first export orders to the US and Korea, which helped diversify the market. Lafooco has also recently received orders from new customers such as a large supermarket chain in Japan and some customers in China. Previously, in 2022, the commercial nut snack product Lafooco entered the top 10 best-selling cashew snack products after only 2 weeks on Amazon...

According to experts and companies, “soft” green growth and sustainable development standards are increasingly popular in import markets. Although it is not a “strict” regulation, early processing to catch up with this trend will help companies' products to have more positives when entering the market. And in the not-so-distant future, these “soft” standards will become mandatory, resulting in the immediate withdrawal of goods that do not meet the requirements of the global game.

Via Bao Hai quan